Welcome to HCS Group, INC.

Below you will find some of our recent projects as well as info on how we have helped some of our clients improve their facility efficiency.

Methodology HCS Leverages On

- Plant Operation Experience

- Engineering/Design Experience

- Experience Across Industries

- Alert to Application of New and Proven Technology from Other Industries

- Expertise That Allows Single Source System Evaluation

- Environmental and Electrical Permitting

- Use of Client’s Knowledge And Personnel Strengths

Integration Approach

Net Reduced Emissions

- CHP (includes utility credit)

Zero Added Emissions

- Waste heat recovery

- High pressure system reduction

- Renewable Solar thermal and PV

- Battery integration

State/Utility Programs

- Low Carbon Fuel Standards (LCFS)

- Efficiency rebate programs

De-carbonization

- C02 Capture

HCS Commitment

To provide independent evaluations, designs, and installations of utility systems which provide facility owners a project for achieving: operational flexibility, environmental compliance, cost effective operations, all services necessary to reach their goals and single point responsibility.

E & P Services

Heavy Oil Production;Provides 5.5 MW Power;

6,445 BPD 70% Steam; Reduced Power Cost 50%;

Reduced $/BBL Cost; Reduced Emission Fees 15%

Paper Recycle

Provides 4 MW of 7 MW Need, Capacity of 30 kpph of Steam

Driven by Change in Utility Contract

Total Cycle Efficiency of > 90%, IRR ~ 50%

Polymer Facility

USEPA-CHP Annual Award Winner

Provides 22 MW of 80 MW Need

Multiple Units Reduced Power Standby Charge

Capacity of 500 kpph of Steam

Total Cycle Efficiency of 89%, IRR ~ 40%

Refining Facility

Provides 8 MW of 20 MW Need, Provides All Steam 80 kpph, avoided new utility charges as well as replaced an aging system.

Doubled Total Cycle Efficiency, IRR ~ 35%

Water Treatment

Provides 3 MW of 4 MW Need. Capacity of 300 gpm Hot Water. Engine Driven Generators on Waste Fuel

Total Cycle Efficiency of > 60%, IRR ~ 35%

Hospital Services

Provides 2 MW of 3 MW Need. Capacity of 650 Ton Chilled or Hot Water. Engine Exhaust and Cooling Water Recovery.

Total Cycle Efficiency of > 60%, IRR ~ 40%.

Corporate Building

Triple Redundant Power Source

- 4.5 MW Cogen

- Utility

- 4.5 MW Portable Generators

Triple Redundant Chilling

- Absorption (1,350-ton)

- Electric (1,200- ton)

- 500k Gallon Thermal Storage (4,000- ton-hr)

Modular Components Approach

BACT Emissions

Bio-Gas Renewable

SWANA Annual Recognition

Combined Cycle Provides 11MW

Power

Landfill & Digester Gas(3 Miles Apart)

Total Cycle Efficiency of > 60%

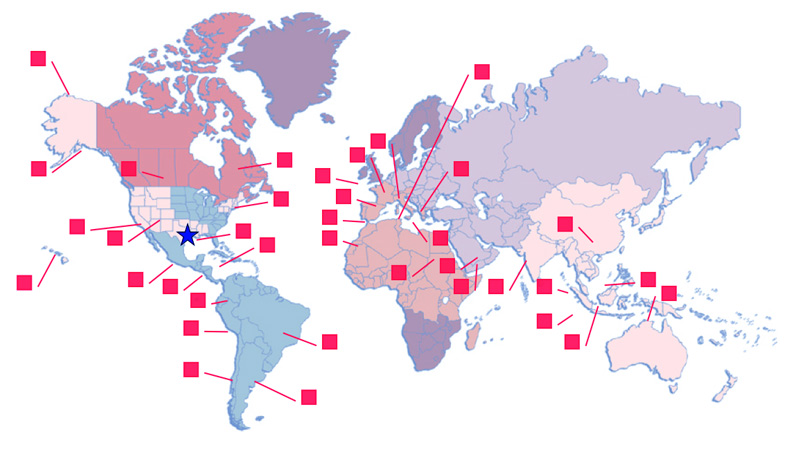

| Facility Type | Services |

|---|---|

| Crude Oil Pipeline – Environmental Permitting and Compliance | Consulting & Engineering |

| Refinery Wastewater | Consulting & Engineering |

| Refinery Wastewater | Consulting |

| LPG Distribution | Consulting & Engineering |

| LPG Distribution | Consulting & Engineering |

| Natural Gas Processing | Consulting & Engineering |

| Cogeneration | Consulting & Engineering |

| Cogeneration – Tire Manufacturing | Consulting |

| LNG Facility | Consulting |

| International Energy Consultants | Consulting |

| Petroleum Refinery Processes | Consulting |

| Fertilizer Manufacturing | Consulting, Engineering, Project Management & Construction |

| Sulfur Processing – Refinery | Consulting |

| Sulfur Removal/Processing - Refinery | Consulting |

| Sulfur Removal/Processing - Refinery | Consulting |

| Sulfur Based Fertilizer Plant | Consulting, Engineering, Project Management & Construction |

| Waste Grease Processing | Consulting & Engineering |

| Offshore Production Facility – Waste Water | Consulting |

| Cogen – Rice Processing Plant | Consulting & Engineering |

| Cogen – Latex Rubber Facility | Consulting |

| Cogen – Synthetic Rubber Facility | Consulting |

| Cogen – Specialty Chemicals | Consulting & Engineering |

| Cogen – Carbon Black Facility | Consulting |

| Cogen – Polymer Facility | Consulting |

| 1MM Pound/Day Polymer Compounding Facility | Engineering, Project Management & Construction |

| Cogen – Polymer Facility | Consulting, Engineering, Project Management & Construction |

| Cogen and Wastewater -Hydrogen Peroxide Facility | Consulting |

| Russian Gas Processing Module | Consulting & Engineering |

| Cogen – Brewing Facility | Consulting |

| Cogen – Brewing Facility | Consulting & Engineering |

| Cogen – Food Processing | Consulting |

| Cogen – Beverage Facility | Consulting |

| Cogen – Distillery | Consulting |

| Cogen – Food Growing/Processing | Consulting |

| Cogen – Tire Manufacturing | Consulting |

| Chemicals Storage, Blending, Packaging | Consulting, Engineering & Project Management |

| Cogen – Petrochemicals | Consulting |

| Cogen – Ethanol Facility | Consulting |

| Cogen – Kraft Paper Plant | Consulting |

| Cogen – Consumer Goods | Consulting |

| Cogen – Elastomer Facility | Consulting & Engineering |

| Wastewater Treatment – Refinery | Consulting, Engineering, Project Management & Construction |

| Cogen – Herbicide Facility | Consulting & Engineering |

| Cogen – Gas Processing Facility | Consulting |

| Cogen – Refinery | Consulting, Engineering, Project Management & Construction |

| Utility Upgrade – Gas Processing Facility | Consulting & Engineering |

| Cogen – Synthetic Rubber Facility | Consulting |

| LNG Expansion Budgeting | Consulting |

| Lube Oil Blending Modifications | Engineering |

| Refinery Process Expansion | Consulting |

| Utilities Upgrade | Consulting, Engineering, Project Management & Construction |

| Cogen – Food Processing | Consulting |

| Cogen – MTBE Production | Consulting |

| Cogen – Tire & Chemical Plant Power Plant | Consulting |

| Energy Audit | Consulting |

| Facility Structural Support Verification and Modifications | Consulting & Engineering |

| Project Assistance – Gas Processing | Engineering & Project Management |

| Cogen – Recycle Paper Plant | Consulting |

| Cogen – Recycle Paper Plant | Consulting |

| Cogen – Recycle Paper Plant | Consulting |

| Cogen – Tire Manufacturing Plant | Consulting |

| Cogen – Tire Manufacturing Plant | Consulting |

| Cogen – Tire Manufacturing Plant | Consulting |

| Cogen – Tire Manufacturing Plant | Consulting |

| Cogen – Tire Manufacturing Plant | Consulting |

| Cogen – Cement Plant | Consulting |

| Industrial Facility Evaluation | Consulting |

| Facility Acquisition of Gas Processing Plant | Consulting |

| Gas Processing Evaluation | Consulting |

| Cogen – Specialty Chemicals | Consulting |

| Cogen – Hospital | Consulting |

| Independent Cost Analysis for LNG Plant | Consulting |

| Cogen – Health Products | Consulting |

| Cogen – Health Products | Consulting |

| Cogen – Central Energy Plant | Consulting & Engineering |

| Cogen – Central Energy Plant | Consulting |

| Cogen – Asbestos Mining/Processing | Consulting |

| Gas Turbine Pipeline Compressor Station | Engineering & Project Management |

| Gas Turbine Pipeline Compressor Station | Engineering & Project Management |

| Cogen – Polyolefin's Plant | Consulting |

| Cogen – Refinery | Consulting & Engineering |

| Simple Cycle Power Plant | Consulting & Engineering |

| Combined Cycle Power Plant | Consulting & Engineering |

| Cogen - Specialty Chemicals | Consulting |

| Cogen – Brewery | Consulting |

| Cogen – Brewery | Consulting |

| Cogen – Polymer Plant | Consulting |

| Project Assistance Ammonia Plant | Consulting & Engineering |

| Industrial Wastewater Treatment | Consulting & Engineering |

| Construction Project Evaluation | Consulting |

| Cogen – Proposed Refinery | Consulting |

| Independent LNG Plant Cost Estimate | Consulting |

| Independent Cost Estimate – Control System Conversion | Consulting |

| Industrial Wastewater Treatment | Consulting |

| Cogen – Specialty Chemicals | Consulting |

| Cogen – Paper Plant | Consulting |

| Cogen – Chemicals Plant | Consulting |

| Cogen – LPG Fractionation | Consulting |

| Cogen using LNG as fuel | Consulting |

| Cogen – Titanium Dioxide Plant | Consulting & Engineering |

| Gas Compression Packages | Engineering |

| Gas Compression Packages | Engineering |

| Cogen – Laminate Products Manufacturing | Consulting |

| Waste Grease Processing Plant | Consulting & Engineering |

| Cogen – Polymer Plant | Consulting |

| Cogen – Animal Food Processing | Consulting |

| Power Production – Landfill Gas | Consulting |

| Cogen – Tire Manufacturing | Consulting |

| Cogen – Heavy Manufacturing Plant | Consulting |

| Cogen – Tire Manufacturing | Consulting |

| Cogen – Utility Power Plant | Cm |

| Cogen – Chemical Additives | Consulting |

| Cogen – Wastewater Biogas | Consulting |

| Cogen – Pharmaceutical | Consulting |

| Cogen – Chemicals | Consulting |

| Cogen – Specialty Chemicals | Consulting |

| Cogen and Power System Upgrade | Consulting |

| Cogen – Proposed Refinery | Consulting |

| Refinery Process Modifications | Consulting |

| Cogen –Minerals Processing | Consulting |

| Power Plant – Gas Processing Facility | Consulting |

| Cogen – Desalination Plant | Consulting |